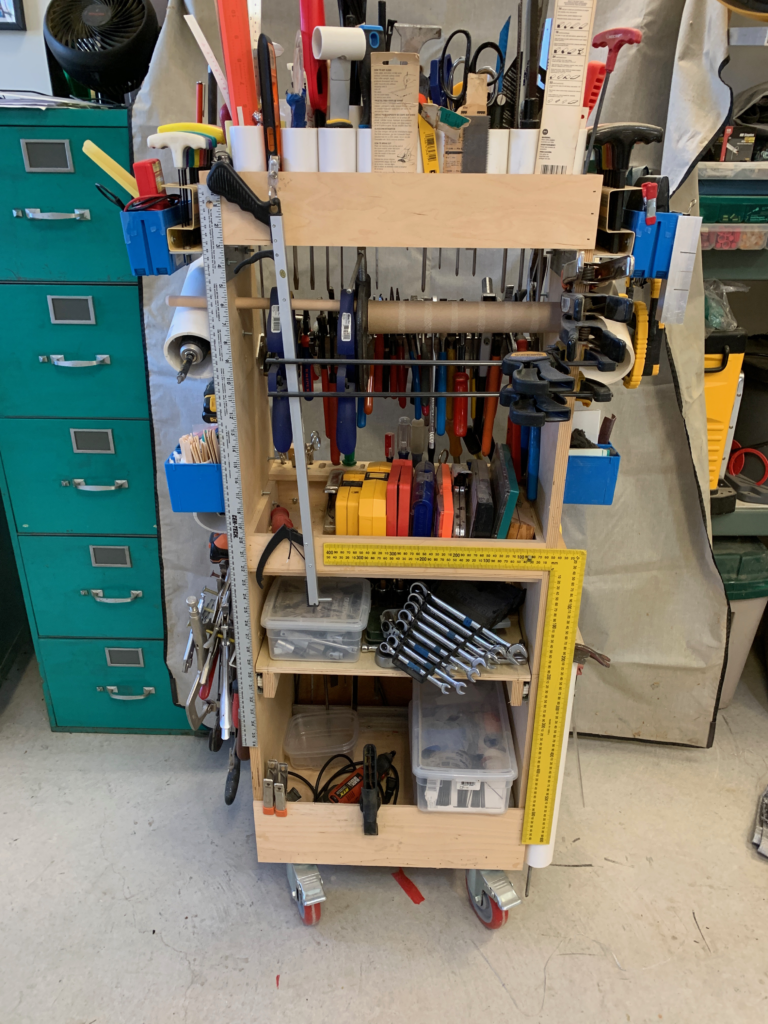

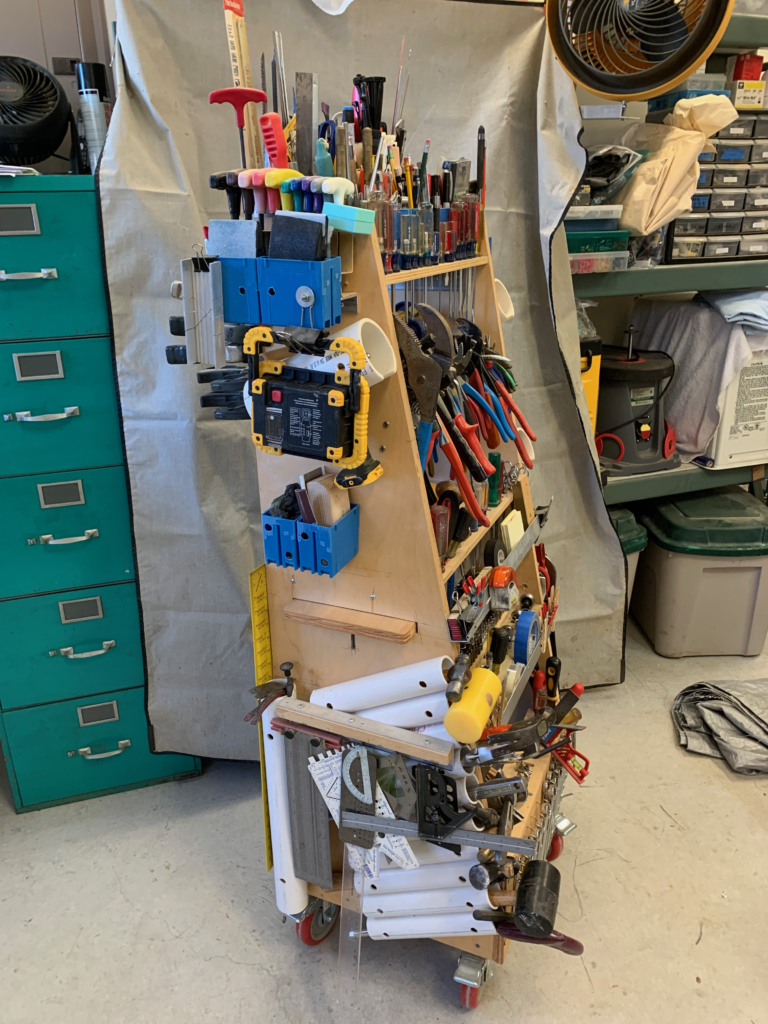

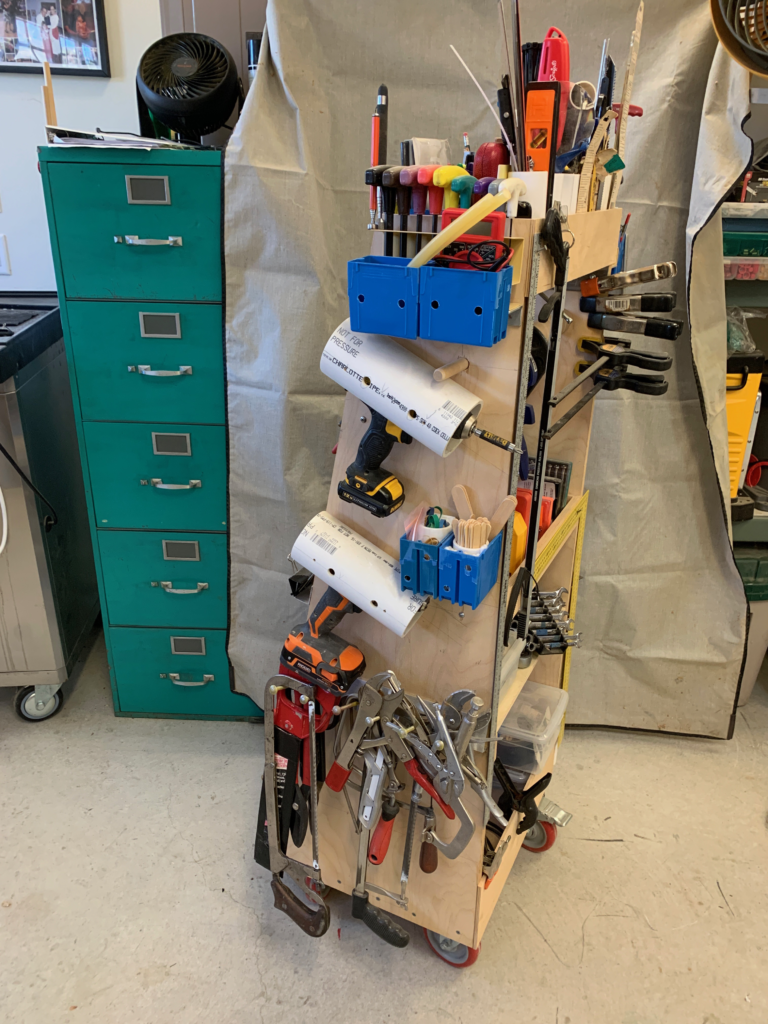

Have your favorite tools always visible and readily available!

I first discovered this type of vertical tool cart design concept watching an online video presented by Adam Savage. Mr. Savage was a co-star on the popular TV series ‘Myth Busters’. He quickly had me sold on the concept given one of my favorite workshop adages over the years has been… if you can’t find it, you don’t have it. My only regret is not discovering this tool cart concept earlier in life.

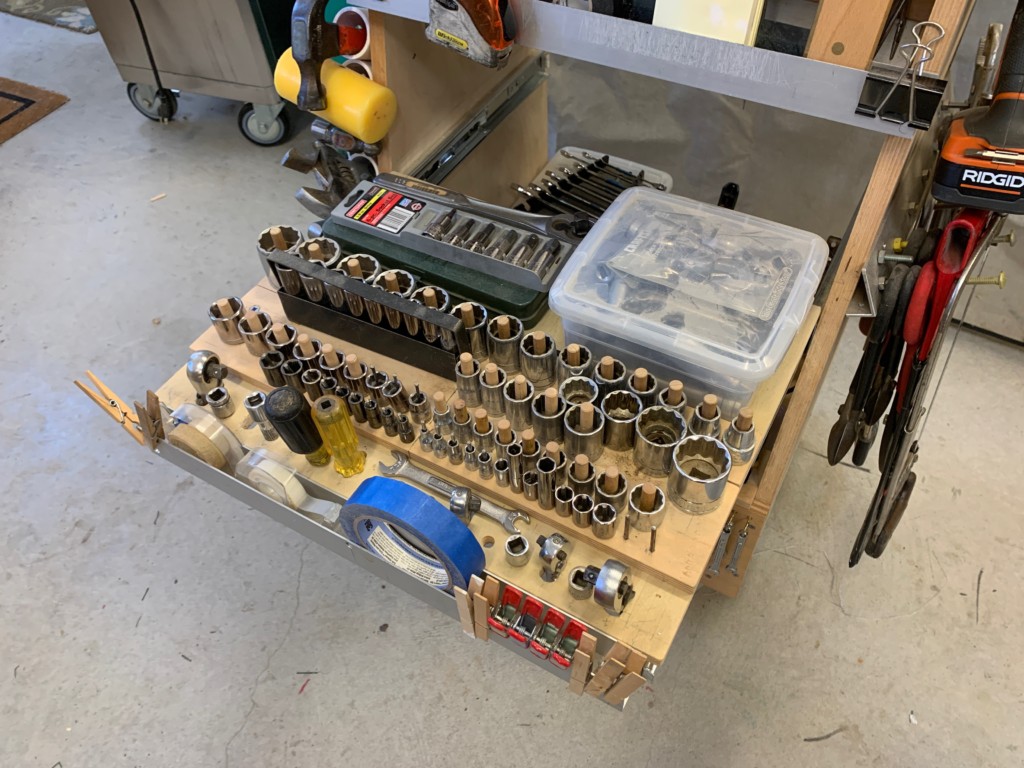

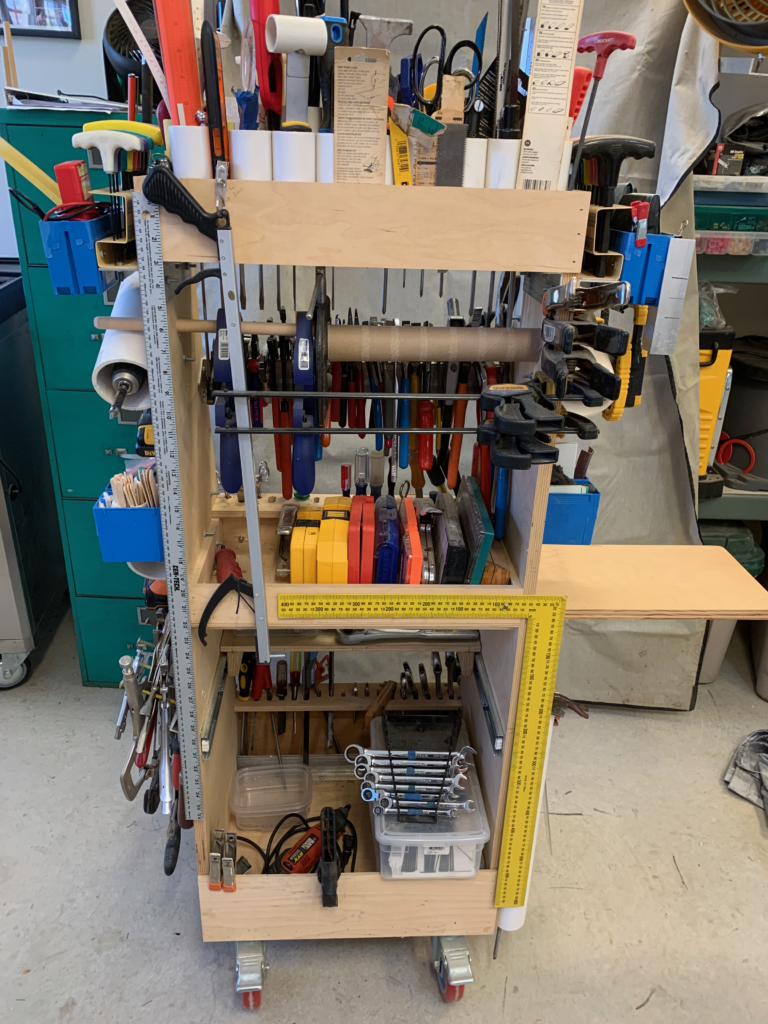

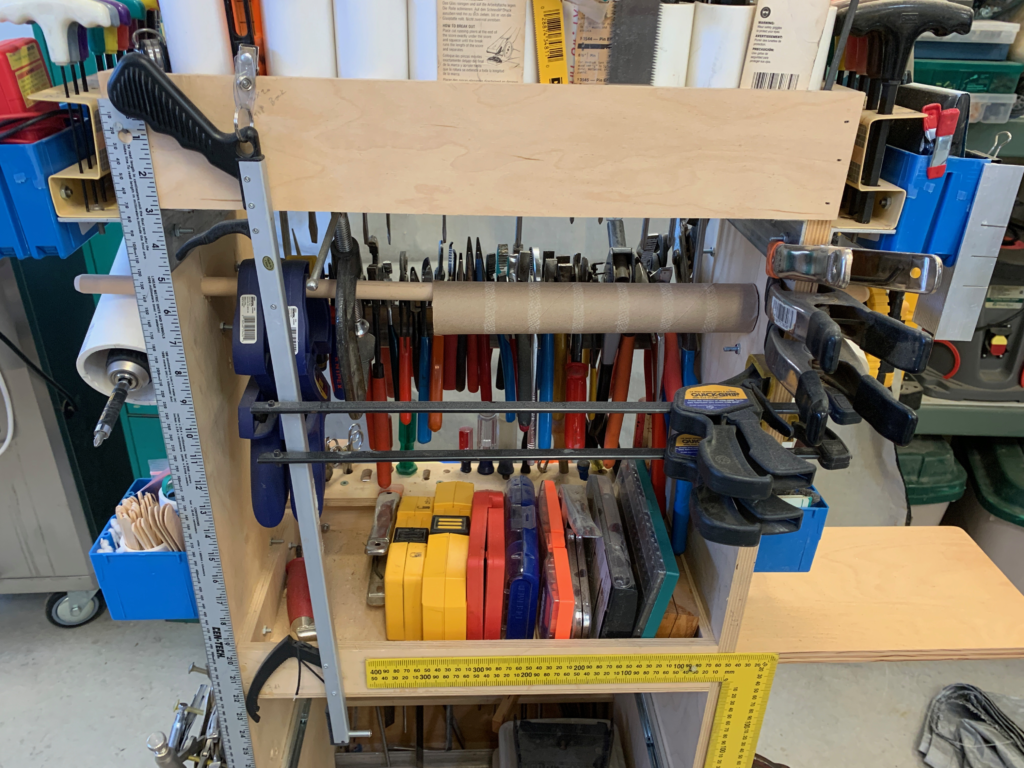

My design process can best be described as two main steps. First, the basic cart shape and dimensions were chosen so the cart could hold as many tools as possible; the tools all needed to be visible and accessible; and the cart had to be easy to move around within workshop. The second piece of the puzzle required gathering all the items that I wanted on the cart and deciding where and how to mount. If you decide to make your own tool cart, I highly recommend that you take some time finalizing your own cart storage requirements. Plus try and leave yourself some unused space on the cart that can be used later for new tools or other items that you missed initially.

Here are the steps I used to get the basic tool cart assembled. First, I assembled the bottom, top (including the center divider), and sides. Then after checking that the basic frame was square, I added the 8″ tall panels to the front and back (bottom end). Now the middle ‘box’ shelf was installed to add rigidity. At this stage, I proceeded to add shelving and containers designed to hold my specific workshops tools and accessories.

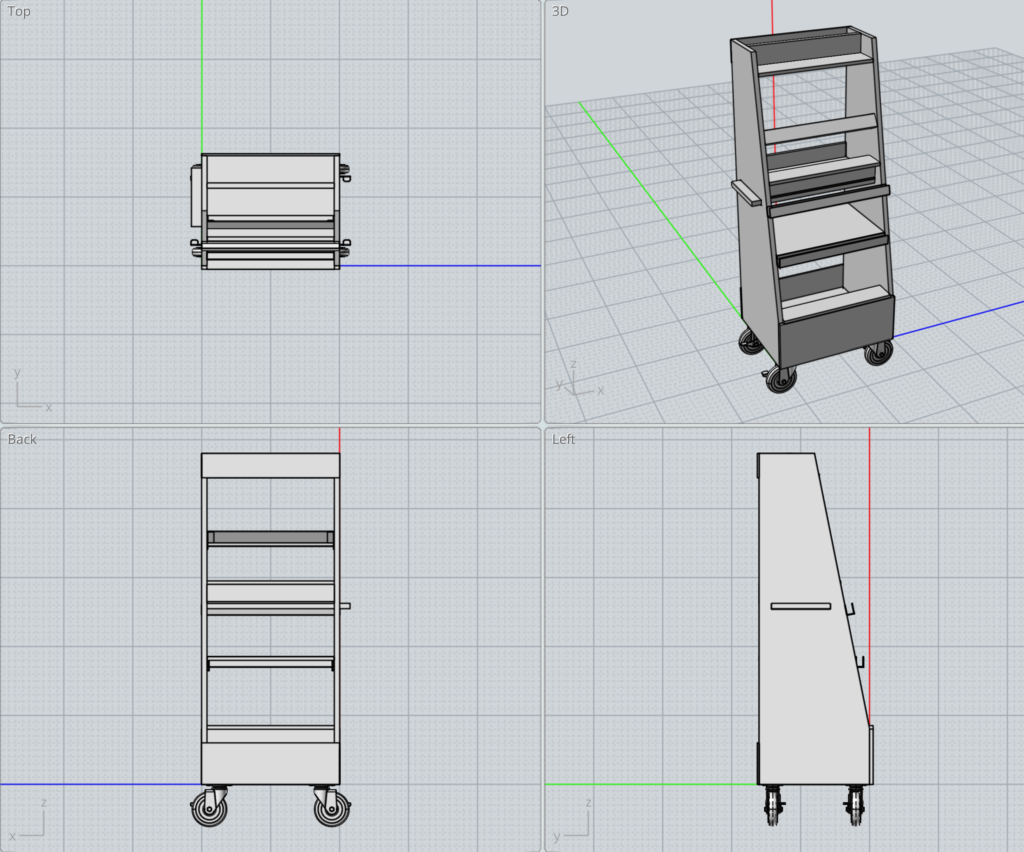

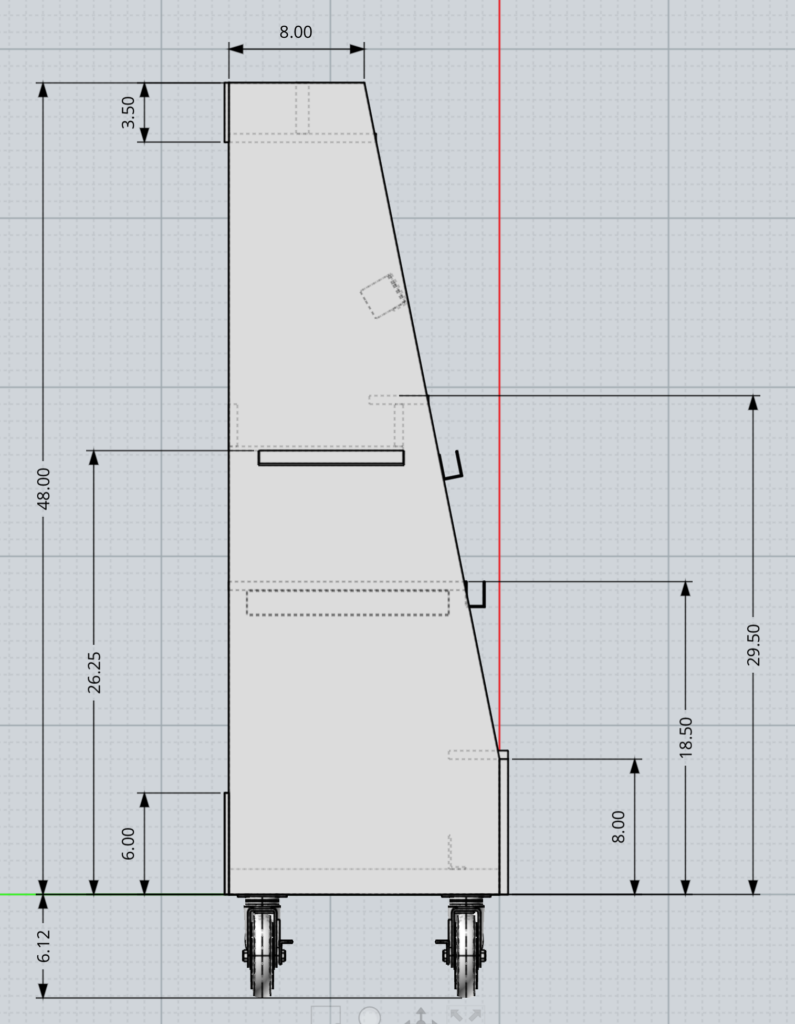

Here are some additional design notes to compliment the 3D model.

- Two pieces of 3/4″ baltic birch plywood were used for the bottom to add strength

- Baltic birch plywood was used to build the basic cart

- The drill holders are 3″ PVC schedule 40 pipe: 3″ dia. x 8″ L with 1 1/2″ wide x 5 3/4″ slot

- 1 1/2″ schedule 40 PVC pipe was used for the horizontal side tubes and the top shelf tubes

- The blue boxes are standard plastic 2 1/4″ x 3 3/4″ x 3 1/4″ H electrical boxes

- The casters are 5″ diameter casters. Smaller diameter wheels would be too small for easy rolling.

- Each caster is bolted to the tool cart using 1/4-20 flat head bolts. The bolts were inserted from the top side into 1/4″ diameter holes with countersinks so the bolt heads were flush with the bottom.

- The L-brackets are 1/8″ x 1″ x 2″ aluminum which I already had.

- The side shelf fits through a slot and has an L-bracket on the bottom to help guide the shelf. This shelf design eventually worked okay after adding some side guides. If making another one, I’d likely just use my router to cut a slot through the shelf and use a bolt plus washer through the slot for the shelf ‘guide’.

Ready to make your own customized tool cart? I’ve provided my 3D CAD model for download which has more details or you can use the model to create your own customized version. The compressed zip file contains three commonly used formats: stp (SketchUp), STEP, OBJECT

3D Model CAD files — zip file: Tool Cart 3D model CAD file

Good ideas! Thanks fort sharing. I think if I build this I will put a power strip above the bottom level and plug various chargers into that, with the chargers sitting on the bottom level. Paper towel dispenser an especially good idea.